A wood screw size chart PDF serves as a detailed guide for selecting the right screws, ensuring proper fitment, and optimizing project results. It simplifies choosing the correct size, type, and material for various applications, saving time and effort while guaranteeing secure joints and professional finishes.

Overview of Wood Screw Size Charts

A wood screw size chart PDF provides a comprehensive overview of screw dimensions, including gauge, diameter, and length. It categorizes screws by type, material, and application, ensuring compatibility with various woodworking projects. These charts often include metric and imperial measurements, making conversions straightforward. They also highlight key features like thread type and head styles, offering a quick reference for DIYers and professionals to select the ideal screws for their tasks efficiently.

Importance of Using a Wood Screw Size Chart

A wood screw size chart PDF is essential for ensuring precision and avoiding costly mistakes. It provides a clear reference guide, helping users select the right screw size, type, and material for their projects. This tool saves time, prevents errors, and guarantees secure joints. By using a size chart, DIYers and professionals can optimize their workflows and achieve durable, professional-quality results in woodworking and construction projects.

Understanding Wood Screw Dimensions

Wood screw dimensions include diameter, length, and thread specifications. These measurements ensure proper fitment and performance. A size chart helps identify the right screw for your project needs.

Gauge and Diameter Measurements

The gauge of a wood screw refers to its diameter, with larger gauges indicating thicker screws. Diameter measurements are crucial for ensuring proper fitment and strength in woodworking projects.

A size chart provides clear comparisons between gauge numbers and actual diameters, helping users match screws to specific materials and applications.

Understanding these measurements prevents overdrilling and ensures secure joints. They are essential for achieving professional results in woodworking and construction tasks.

Length and Thread Specifications

The length of a wood screw is crucial for ensuring proper hold in materials. Standard lengths range from 1/4 inch to 4 inches, depending on the application. Threads are designed in coarse or fine patterns, with coarse threads offering better grip in softer woods and fine threads providing strength in hardwoods. A wood screw size chart PDF details these specifications, enabling precise selection for optimal performance and durability in various woodworking projects.

Types of Wood Screws

Wood screws come in various types, including deck, drywall, and machine screws, each designed for specific applications. Specialized screws offer tailored solutions for unique needs.

Common Wood Screw Types

Wood screws are available in various common types, each suited for specific tasks. Deck screws are ideal for outdoor projects, offering rust resistance and durability. Drywall screws feature coarse threads for secure plasterboard fastening. Machine screws are precision-made for metal-to-wood applications. Understanding these types helps in selecting the right screw for your project, ensuring strength and reliability in woodworking and construction applications.

Specialized Wood Screw Varieties

Beyond standard screws, specialized varieties offer tailored solutions. Self-tapping screws drill and thread in one step, ideal for metal-to-wood applications. Structural screws provide exceptional strength for heavy-duty tasks. Trim screws feature small heads for a clean finish, while lag screws handle large-scale projects. These specialized options ensure optimal performance for unique woodworking challenges, enhancing both functionality and aesthetics in custom designs and industrial-grade constructions.

Wood Screw Materials and Coatings

Wood screws are made from materials like steel, stainless steel, and brass, with coatings such as zinc plating, galvanized, or epoxy for enhanced durability and corrosion resistance.

Common Materials Used for Wood Screws

Wood screws are typically made from durable materials like steel, stainless steel, and brass. Steel screws are the most common due to their strength and affordability. Stainless steel screws offer excellent corrosion resistance, ideal for outdoor projects. Brass screws are corrosion-resistant and often used for decorative woodworking. These materials ensure screws withstand various environmental conditions and provide long-lasting performance in woodworking applications.

Coatings and Treatments for Durability

Wood screws often feature coatings like galvanized or zinc-plated finishes to enhance corrosion resistance. Stainless steel screws naturally resist rust, making them ideal for outdoor use. Some screws are treated with epoxy or ceramic coatings for added protection. These coatings ensure screws withstand harsh environments and maintain their integrity over time, providing reliable performance in various woodworking and construction projects.

Wood Screw Head Types

Wood screws feature various head types, including flat, round, and hex, each designed for specific applications. These heads provide different levels of flush seating and torque capability.

Flat, Round, and Hex Head Options

Wood screws are available with flat, round, or hex heads, each offering unique benefits. Flat heads provide a flush surface, ideal for decorative projects, while round heads are commonly used in furniture. Hex heads, with their six-sided design, offer superior torque and are perfect for heavy-duty applications. Choosing the right head type ensures both functionality and aesthetics, making it easier to achieve professional results in woodworking projects.

Drive Types (Phillips, Flathead, etc.)

Wood screws feature various drive types, including Phillips, Flathead, and Pozidriv. Phillips screws offer excellent torque resistance, reducing cam-out risks. Flathead screws are ideal for applications requiring a flush surface. Pozidriv screws provide even greater torque and are commonly used in construction. Each drive type is included in wood screw size charts, ensuring compatibility with specific tools and projects, enhancing both convenience and performance in woodworking tasks.

Gauge and Diameter Guide

The gauge indicates screw thickness, while diameter measures the screw’s width. Understanding these measurements ensures proper compatibility with materials and tools, essential for secure and precise fastening in woodworking projects.

Understanding Screw Gauge Systems

Screw gauge systems measure thickness, with higher numbers indicating thinner screws. For woodworking, gauges range from 6 (thickest) to 14 (thinnest). Understanding gauge ensures compatibility with drill bits and materials, preventing wood splitting. Charts often pair gauge with screw length and type, helping users match fasteners to project needs for optimal hold and durability, ensuring secure joints and professional results.

Converting Between Imperial and Metric Sizes

Converting between imperial and metric sizes is crucial for international projects. Screw gauges and diameters vary slightly, with metric sizes often using millimeters and imperial using inches. A wood screw size chart PDF typically includes conversion tables, ensuring compatibility. For example, a #10 gauge screw is roughly 4;87mm in diameter. Accurate conversions prevent fitting errors, allowing seamless integration of materials and tools across regions and standards.

Screw Length and Shank Diameter

Screw length and shank diameter are critical for ensuring proper hold and durability. Standard lengths range from 1/2″ to 6″, with shank diameters slightly larger than thread diameters, optimizing strength and fit for various woodworking projects.

Standard Lengths for Wood Screws

Standard lengths for wood screws range from 1/2″ to 6″, with common sizes including 1″, 1-1/2″, 2″, and 3″. These lengths ensure proper hold without over-sinking or under-sinking. Choosing the right length is crucial for securing materials effectively, preventing splitting, and ensuring structural integrity. Always match the screw length to the combined thickness of the materials being joined for optimal results in woodworking projects.

Shank Diameter vs. Thread Diameter

The shank diameter is the smooth, unthreaded portion of the screw, while the thread diameter includes the threaded section. The shank is typically larger than the thread diameter to prevent splitting the wood. This design ensures proper hold and reduces the risk of material damage. Understanding these measurements is crucial for selecting the right screw size and type, as outlined in a wood screw size chart PDF for accurate project planning.

Thread Specifications

Thread specifications in wood screws refer to the spacing and depth of threads. Coarse threads provide stronger hold in softer materials, while fine threads offer precision in hardwoods. A wood screw size chart PDF details these measurements, ensuring proper screw selection for various woodworking projects and materials.

Coarse vs. Fine Threads

Coarse threads are larger and spaced farther apart, offering superior holding power in softer woods. Fine threads are smaller and closer together, ideal for hardwoods to prevent splitting. A wood screw size chart PDF provides detailed comparisons, helping users select the optimal thread type for their project needs, ensuring strength and durability in various woodworking applications.

Thread Pitch and Depth

Thread pitch refers to the distance between consecutive threads, while thread depth measures the height of the thread. A wood screw size chart PDF outlines these measurements, helping users understand how thread pitch and depth affect holding power and material compatibility. Coarser pitches are often used for softer woods to minimize splitting, while finer pitches provide better grip in hardwoods. Proper thread depth ensures secure fastening without compromising material integrity.

Drive Types and Compatibility

Wood screw size charts detail drive types like Phillips, flathead, and hex, ensuring compatibility with drivers. Matching drive types prevents screw damage and ensures secure fastening.

Common Drive Types for Wood Screws

Wood screws feature various drive types, including Phillips, flathead, and hex. Phillips screws provide excellent torque resistance, reducing cam-out. Flathead screws are ideal for flush surfaces, while hex (or Allen) screws offer superior grip for heavy-duty applications. Each drive type requires a compatible driver to ensure proper installation and prevent damage. Using the correct driver enhances screw performance and project durability.

Choosing the Right Driver

Selecting the correct driver is crucial for effective screw installation. Phillips drivers are ideal for screws with a cross-shaped recess, while flathead drivers suit slotted screws. Hex or Allen drivers are designed for screws with a hexagonal recess, providing maximum torque. Using the wrong driver can damage the screw head or strip the recess, compromising the screw’s hold. Always match the driver to the screw type for secure and efficient fastening.

Applications of Wood Screws

Wood screws are essential for woodworking projects, construction, and decking. They ensure strong joints and durability in various applications, from furniture making to outdoor decking, guided by size charts for optimal results.

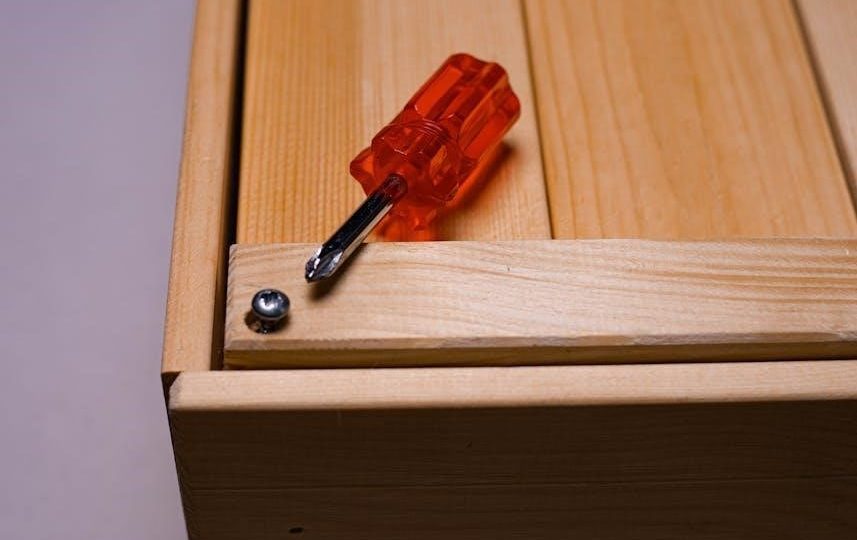

Woodworking Projects

Wood screws are indispensable in woodworking projects, ensuring strong and durable joints. They are ideal for furniture making, cabinetry, and DIY tasks. Using a size chart guarantees proper fitment and longevity. It helps select the right screw type, material, and length for each application, ensuring projects are secure and professional. This guidance is essential for both professionals and DIY enthusiasts to achieve high-quality results in their woodworking endeavors.

Construction and Decking

Wood screws are vital in construction and decking, providing strength and durability for outdoor structures. They are designed to withstand harsh weather conditions and heavy loads. A size chart helps contractors and professionals choose the right screws for decking materials, ensuring secure and long-lasting joints. Proper screw selection prevents structural issues and enhances safety in construction projects, making it a crucial tool for achieving reliable results in building and renovation tasks.

How to Use a Wood Screw Size Chart

A wood screw size chart PDF helps you quickly identify the right screw for your project, saving time and ensuring secure joints. Use it to match screw size, material, and length to your needs for precise results.

Matching Screw Size to Your Project

Using a wood screw size chart PDF ensures you select screws that perfectly match your project’s requirements. By referencing the chart, you can determine the appropriate gauge, length, and type of screw for your materials. This prevents over- or under-fastening, ensuring secure joints and preventing material damage. The chart also helps in choosing the right screw for specific woodworking tasks, enhancing both functionality and aesthetics in your work. It’s a practical tool for both professionals and DIYers.

Interpreting the Chart for DIY and Professional Use

A wood screw size chart PDF is a versatile tool for both DIY enthusiasts and professionals. It provides standardized measurements for screw sizes, gauges, and lengths, ensuring accurate selections. For DIY projects, the chart simplifies screw choice, reducing confusion. Professionals benefit from consistent, reliable data, enhancing project quality. The chart also highlights material compatibility and coatings, helping users avoid common errors and ensure secure, durable joints in various woodworking applications.

Common Mistakes to Avoid

Common errors include selecting the wrong screw size, ignoring material compatibility, and improper metric-imperial conversions. These mistakes can lead to weak joints or project failure.

Incorrect Screw Size Selection

Incorrect screw size selection is a common mistake that can lead to weak joints or structural failure. Using screws that are too small may result in insufficient holding power, while oversized screws can split the wood. Always refer to a wood screw size chart PDF to match screw dimensions with your project’s requirements, ensuring proper fit and durability. Double-check measurements to avoid costly errors and ensure a professional finish.

Ignoring Material and Coating Requirements

Overlooking material and coating requirements can compromise a project’s durability and safety. For example, using untreated steel screws in outdoor applications can lead to rust and weakness. Coatings like galvanized or epoxy protect against corrosion, while specialized materials such as brass or stainless steel are ideal for specific environments. Always consult a wood screw size chart PDF to ensure the right materials and coatings are selected for your project’s conditions.

Downloading a Wood Screw Size Chart PDF

Download a free wood screw size chart PDF for easy reference. These charts provide standard sizes, measurements, and types, perfect for DIY projects and professional use.

Free Resources for Wood Screw Charts

Free wood screw size chart PDFs are widely available online, offering comprehensive guides for DIY enthusiasts and professionals. Websites like McFeelys and Fine Power Tools provide detailed charts with standard sizes, measurements, and types. These resources are print-friendly and include conversion guides between imperial and metric systems, ensuring accuracy for various woodworking projects. Downloading these charts saves time and ensures you have the right screw sizes for your needs.

Printing and Using the Chart Effectively

Printing a wood screw size chart PDF ensures a handy reference for projects. Choose high-quality print settings for clear visibility of sizes and measurements. Laminate the chart for durability and keep it in your workshop or toolbox. Use it to quickly match screw sizes to your needs, ensuring accuracy and efficiency in woodworking and construction tasks. This tool is invaluable for both DIY enthusiasts and professionals alike.

Using a wood screw size chart PDF ensures accuracy and efficiency, helping you avoid common mistakes and achieve professional results in woodworking and construction projects.

Final Tips for Selecting the Right Wood Screws

Always verify screw measurements using a size chart to ensure compatibility with your project. Consider the material and coating for durability, especially in outdoor or high-moisture environments. Match the screw type to your driver for ease of use, and consult manufacturer guides for specific applications. Organizing screws by size before starting can save time and reduce errors. Prioritize quality to ensure long-lasting results in woodworking and construction projects.