Monobond Plus is a universal primer designed to create a strong bond between luting composites and various restorative materials, ensuring durable and reliable adhesion in dental restorations.

1.1 What is Monobond Plus?

Monobond Plus is a single-component, universal primer designed to create a durable chemical bond between luting composites and various restorative materials. It is specifically formulated for use with indirect restorations, including glass ceramics, metals, and zirconia. The primer contains methacrylate monomers, which ensure excellent adhesion and compatibility with a wide range of materials. Its universal nature makes it suitable for bonding luting composites to glass/oxide ceramics, metal, and zirconia surfaces. Monobond Plus is part of the Ivoclar Vivadent product line and is known for its ease of application and reliable performance. It is an essential component in the adhesive process chain, ensuring long-lasting and stable bonds in dental restorations. The product is available as a ready-to-use solution, simplifying the bonding procedure for dental professionals. Its effectiveness has been clinically proven, making it a trusted choice in modern dentistry;

1.2 Key Components of Monobond Plus

Monobond Plus is a single-component primer containing methacrylate monomers, which are essential for creating a strong adhesive bond between luting composites and restorative materials. Its universal formulation makes it compatible with glass ceramics, metals, and zirconia. The methacrylate monomers ensure excellent adhesion and durability, while its ethanol-based solution facilitates easy application and evaporation. The product is designed for indirect restorations, offering a reliable bond that withstands various stresses in the oral environment. Its key components work synergistically to enhance the bonding process, ensuring long-term clinical success. Monobond Plus is part of Ivoclar Vivadent’s comprehensive range of dental products, known for their high quality and innovative solutions in modern dentistry.

Indications and Applications

Monobond Plus is used for bonding luting composites to glass ceramics, metals, and zirconia restorations, ensuring durable adhesion in various dental applications.

2.1 Glass Ceramic Restorations

Monobond Plus is specifically designed for use with glass ceramic restorations, ensuring a strong and durable bond between the ceramic surface and luting composites. Its universal bonding properties make it an ideal choice for creating a reliable adhesion in glass ceramic applications. The primer is applied after surface preparation, which typically involves etching with hydrofluoric acid to create microretention and improve the bonding interface. Once the surface is properly prepared, Monobond Plus is applied using a brush or applicator and allowed to react for 60 seconds. This step ensures optimal bonding between the ceramic and the luting material, reducing the risk of restoration failure. The product’s single-component formula simplifies the application process, making it a efficient and effective solution for dental professionals working with glass ceramic restorations. Its compatibility with various luting composites further enhances its versatility in clinical applications.

2.2 Metal Restorations

Monobond Plus is highly effective for metal restorations, providing a strong and durable bond between metal surfaces and luting composites. Its universal bonding properties make it suitable for various metal-based restorations, ensuring long-term stability and reliability. Prior to application, metal surfaces are typically prepared through sandblasting to create a microretentive surface, which enhances adhesion. Once the surface is properly prepared, Monobond Plus is applied evenly using a brush or applicator. The primer is allowed to react for approximately one minute before air drying, ensuring optimal bonding between the metal and the luting material. This process minimizes the risk of restoration failure and ensures a stable, long-lasting bond. The product’s single-component formula and ease of use make it a preferred choice for dental professionals working with metal restorations. Its compatibility with various luting composites further enhances its versatility in clinical applications, making it a reliable solution for achieving durable metal restorations.

2.3 Zirconia Restorations

Monobond Plus is specifically designed to enhance the bonding performance for zirconia restorations, ensuring a strong and durable bond between zirconia surfaces and luting composites. Zirconia, known for its high strength and biocompatibility, requires proper surface preparation to achieve optimal adhesion. After pre-treatment steps such as sandblasting or cleaning with Ivoclean, Monobond Plus is applied evenly to the zirconia surface using a brush or applicator. The primer reacts for 60 seconds, creating a stable chemical bond. It is highly recommended for use with zirconia oxide surfaces, as it effectively addresses the challenges of bonding to this material. Monobond Plus is compatible with a wide range of luting composites, making it a versatile choice for zirconia restorations. Its single-component formula simplifies the application process, ensuring efficient and reliable bonding. This makes it an excellent solution for achieving long-lasting zirconia restorations with minimal risk of post-bonding failures.

Instructions for Use

Monobond Plus requires precise surface preparation, followed by application with a brush or applicator. Allow the primer to react for 60 seconds before air-drying excess material for optimal bonding performance.

3.1 Surface Preparation

Surface preparation is critical for effective bonding with Monobond Plus. For glass ceramic restorations, etch with hydrofluoric acid for 20 seconds, rinse thoroughly with water, and dry with oil-free air. For zirconia, clean the surface with Ivoclean for 20 seconds, rinse, and dry. Sandblasting may also be used as a pre-treatment for certain materials to enhance surface roughness. Ensure the restoration is free of contaminants and completely dry before applying Monobond Plus. Proper preparation ensures optimal bonding performance and durability of the restoration.

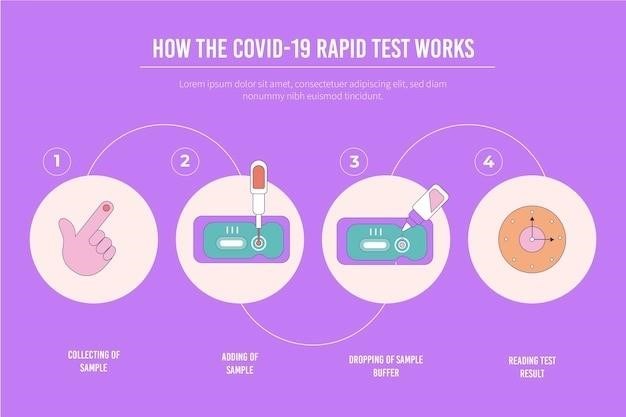

3.2 Application Process

Apply Monobond Plus evenly to the prepared surface using a brush or microbrush. Ensure complete coverage of the restoration surface for optimal bonding. Allow the primer to react for 60 seconds to enable proper bonding. After the reaction time, gently air-dry the surface to remove excess liquid. Avoid contamination during the application process. For glass ceramic restorations, apply Monobond Plus immediately after etching and drying. For zirconia or metal restorations, apply the primer following sandblasting and cleaning with Ivoclean. The application process is straightforward and ensures a strong, durable bond between the restoration and luting composite; Proper technique is essential to achieve the best results.

3.3 Reaction Time

The reaction time for Monobond Plus is a critical step in ensuring proper adhesion. After applying the primer to the prepared surface, allow it to react for exactly 60 seconds. This time enables the active ingredients to interact with the material, creating a strong bond. During this period, avoid disturbing or contaminating the surface. The reaction time is consistent across all types of restorative materials, including glass ceramic, metal, and zirconia. It is important not to rush this step, as insufficient reaction time may compromise the bonding efficiency. Once the reaction is complete, proceed with air-drying the surface to remove any excess liquid. Proper adherence to the recommended reaction time ensures optimal bonding performance and longevity of the restoration. This step is essential for achieving a reliable and durable bond between the restoration and the luting composite.

3.4 Air Drying

Air drying is a final step in the Monobond Plus application process, ensuring the surface is free from excess liquid. After the reaction time of 60 seconds, any remaining primer should be gently air-dried using oil-free air. This step is crucial to prevent contamination and ensure a clean, stable surface for bonding. Air drying should be done carefully to avoid blowing away the primer or introducing debris. The process is consistent across all types of restorative materials, including glass ceramic, metal, and zirconia. Proper air drying ensures the primer is evenly distributed and ready for the next step in the restorative process. It is important to use oil-free air to prevent any residues that could interfere with the bonding process. This step completes the preparation of the surface, ensuring optimal conditions for a strong and durable bond.

Pre-treatment Steps

Pre-treatment steps are essential for ensuring proper surface preparation and adhesion. This includes etching, sandblasting, or cleaning with Ivoclean to create an optimal surface for Monobond Plus application.

4.1 Etching with Hydrofluoric Acid

Etching with hydrofluoric acid is a critical pre-treatment step for glass ceramic restorations. Apply the acid for 20 seconds to ensure proper surface preparation and microretention. After etching, rinse thoroughly with water spray and dry the surface with oil-free air. This step creates a porous surface, enhancing the bonding efficiency of Monobond Plus. Always handle hydrofluoric acid with care, as it is corrosive and can cause skin irritation. Use protective gloves and eyewear during the process. The etching step is essential for achieving a strong and durable bond between the ceramic surface and the adhesive. Proper rinsing and drying are necessary to avoid any residual acid interfering with the bonding process. Follow the manufacturer’s instructions for concentration and application time to ensure optimal results. This step is not required for metal or zirconia restorations, where sandblasting is typically preferred. Etching with hydrofluoric acid is specific to ceramic materials, making it a key step in their preparation for Monobond Plus application.

4.2 Sandblasting

Sandblasting is a common pre-treatment method for metal and zirconia restorations to create a rough surface texture, enhancing the adhesion of Monobond Plus. Use aluminum oxide particles (50–110 μm) at low pressure to avoid damaging the material. After sandblasting, clean the restoration thoroughly with Ivoclean to remove any residues or contaminants. This step ensures a clean, roughened surface for optimal bonding. Sandblasting is not typically used for glass ceramic restorations, as etching with hydrofluoric acid is preferred. For zirconia, sandblasting followed by cleaning with phosphoric acid and drying is recommended. Always wear protective gear during sandblasting to avoid injury. Proper sandblasting and cleaning are crucial for achieving a strong bond between the restoration and the adhesive. This method is essential for metal and zirconia surfaces, ensuring a durable and reliable bond when used with Monobond Plus. Follow manufacturer guidelines for pressure and particle size to achieve the best results.

4.3 Cleaning with Ivoclean

Cleaning with Ivoclean is a critical step after surface preparation, ensuring the removal of any residues or contaminants. Apply Ivoclean to the entire restoration surface, allowing it to react for 20 seconds. Thoroughly rinse the surface with water spray and dry it with oil-free air to prevent any interference with the bonding process. This step is essential for metal, zirconia, and glass ceramic restorations, as it ensures a clean surface for Monobond Plus application. Ivoclean effectively removes sandblasting residues, acid byproducts, or other impurities, promoting optimal adhesion. Proper cleaning enhances the durability and reliability of the bond between the restoration and the adhesive. Always follow the manufacturer’s instructions for Ivoclean use to achieve the best results. This step is vital for ensuring a contamination-free surface, which is prerequisite for successful bonding with Monobond Plus.

Safety Precautions

Monobond Plus is an irritant; avoid contact with skin and mucous membranes. Store in a cool, dry place, away from direct sunlight. Dispose of waste according to local regulations. Handle with care.

5.1 Handling Precautions

Monobond Plus is classified as an irritant, and proper handling is essential to avoid adverse reactions. Always wear protective gloves and eye protection when working with the product. Avoid direct contact with the skin or mucous membranes, as this may cause irritation or discomfort. In case of accidental contact, rinse the affected area thoroughly with water. If irritation persists, seek medical advice. Work in a well-ventilated area to minimize exposure to vapors. Avoid ingestion, as this may lead to gastrointestinal discomfort. If swallowed, do not induce vomiting and seek immediate medical attention. Keep Monobond Plus out of reach of children and pets. Proper handling ensures a safe and effective bonding process in dental procedures. Always follow the manufacturer’s guidelines for use and safety.

5.2 Storage Recommendations

Monobond Plus should be stored in a cool, dry place, away from direct sunlight and moisture. The ideal storage temperature is between 15°C and 25°C (59°F to 77°F). Keep the product in its original container, tightly sealed, to prevent contamination and exposure to air. Avoid freezing, as this may alter the product’s properties. Store the primer away from incompatible materials, such as strong oxidizing agents, to prevent chemical reactions. Ensure the product is out of reach of children and pets. Do not use Monobond Plus after its expiration date, which is printed on the container. Regularly check the expiration date to ensure the product remains effective. For unused portions, follow proper disposal guidelines to minimize environmental impact. Always refer to the product’s labeling or instructions for specific storage requirements. Proper storage ensures the primer’s performance and longevity, supporting reliable bonding in dental applications.

5.3 Disposal Guidelines

Disposal of Monobond Plus and its components must adhere to local, state, and federal regulations regarding hazardous waste. Properly dispose of unused product, contaminated materials, and packaging in accordance with applicable environmental laws. Do not pour Monobond Plus down drains or mix it with other waste, as it may contaminate waterways. Use personal protective equipment (PPE) when handling waste to avoid skin and eye contact. Dispose of the product in a sealed container, clearly labeled as hazardous waste, to prevent accidental exposure. Ensure all containers are tightly closed and appropriately labeled before disposal. For large quantities, consult local waste management authorities or certified hazardous waste disposal services. Always follow the manufacturer’s guidelines and safety data sheet (SDS) recommendations for proper disposal. Proper disposal practices help protect the environment and ensure compliance with regulatory requirements; If unsure about specific disposal methods, contact local environmental agencies or the product supplier for guidance.

Contraindications

Monobond Plus is contraindicated in situations where proper bonding cannot be achieved due to incompatible materials or insufficient surface preparation. It should not be used on patients with known allergies to methacrylates or other components of the product; Additionally, Monobond Plus is not recommended for use in cases where the restoration requires a temporary or provisional bond, as it is designed for permanent adhesion. It is also contraindicated for use on unrestored teeth or in areas with active decay or infection, as this may compromise the bonding process and lead to clinical failure. Monobond Plus should not be applied to surfaces that are not properly pretreated, as this may result in inadequate adhesion. Furthermore, it is not suitable for use with materials that are not compatible with methacrylate-based primers. Always ensure the material is used in accordance with the manufacturer’s instructions to avoid unintended clinical outcomes.

Integration with Other Products

Monobond Plus is designed to integrate seamlessly with a variety of dental restorative materials and systems, enhancing the overall bonding process. It is commonly used in conjunction with luting composites such as Variolink Esthetic and Adhese Universal for optimal bonding results. Additionally, Monobond Plus works well with Ivoclean for surface cleaning and preparation, ensuring a contamination-free surface for bonding. The product is also compatible with zirconia, metal, and glass ceramic restorations, making it a versatile choice for diverse clinical needs. Its universal compatibility ensures that it can be incorporated into existing workflows without requiring additional specialized products. By integrating Monobond Plus with other Ivoclar Vivadent systems, clinicians can achieve predictable and long-lasting outcomes in dental restorations. Always refer to the instructions for use of each product to ensure proper integration and compatibility.

Clinical Evidence

Monobond Plus has demonstrated reliable performance in clinical settings, supported by studies showcasing its effectiveness in creating durable bonds between luting composites and various restorative materials. Research indicates that its universal formulation ensures consistent adhesion across materials like zirconia, metal, and glass ceramics. Clinical trials highlight that restorations treated with Monobond Plus exhibit high longevity, with minimal instances of bond failure over time. Its compatibility with renowned systems such as Variolink Esthetic further underscores its credibility. Additionally, Monobond Plus meets ISO standards, reinforcing its adherence to industry benchmarks for dental materials. These findings suggest that Monobond Plus is a dependable choice for clinicians seeking predictable and successful outcomes in adhesive dentistry. Its integration into established workflows aligns with evidence-based practices, supporting its role in contemporary dental restoration techniques.

Troubleshooting

Common issues include incomplete drying or contamination. Ensure proper surface preparation and application as per instructions. Avoid exposure to moisture before bonding. Follow manufacturer guidelines to resolve application-related problems effectively.

9.1 Common Issues During Application

Common issues during the application of Monobond Plus may include incomplete drying, contamination, or improper surface preparation. Inadequate reaction time or high humidity can prevent the primer from drying properly, leading to weak adhesion. Contamination from saliva, blood, or other substances can compromise the bonding process. Additionally, applying too thick a layer or not following the recommended surface pre-treatment steps, such as etching or sandblasting, can result in suboptimal bonding. To address these issues, ensure all surfaces are clean and dry before application. Avoid applying the primer in excessively moist environments and strictly adhere to the instructions for reaction time. If contamination occurs, thoroughly clean and re-prepare the surface before reapplying Monobond Plus. Proper adherence to the manufacturer’s guidelines is essential to achieve a reliable and durable bond.

9.2 Post-Bonding Failures

Post-bonding failures with Monobond Plus can occur due to several factors, including improper surface preparation, contamination, or insufficient reaction time. Incomplete drying of the primer or exposure to high humidity may lead to weak adhesion. Additionally, inadequate etching or sandblasting of the restoration surface can reduce bond strength. Improper handling or accidental contact with contaminants like saliva or blood can also compromise the bond. To prevent post-bonding failures, ensure all surfaces are thoroughly cleaned and dried before applying Monobond Plus. Avoid applying the primer in overly moist environments and strictly adhere to the recommended reaction time. If contamination occurs, restart the bonding process with proper surface preparation. Regular inspection of bonded restorations can help identify and address potential issues early. Following the manufacturer’s instructions and maintaining proper clinical protocols are essential to achieving long-term durability and success with Monobond Plus.

Monobond Plus is a highly effective universal primer designed to enhance the bond between luting composites and various restorative materials. Its ease of use and versatility make it a reliable choice for dental professionals, ensuring durable and long-lasting restorations. By following the instructions carefully, clinicians can achieve optimal bonding results across a wide range of materials, including glass ceramics, metals, and zirconia. Proper surface preparation and adherence to the recommended application process are key to maximizing the product’s performance. Monobond Plus stands out for its ability to simplify the bonding procedure while maintaining high-quality outcomes. Dental professionals are encouraged to utilize Monobond Plus in their clinical practice to ensure successful and predictable results in indirect restorations.